|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Sun Jul 15, 2007 6:21 pm Posted: Sun Jul 15, 2007 6:21 pm |

|

|

| StevieLaner7777 |

| Moderator |

|

|

| Joined: 07 Mar 2007 |

| Posts: 1060 |

| Location: Herefordshire, UK |

|

|

|

Hi

Update on the suppressor project:

At the moment the 'workshop' seems to be lacking in 30mm steel tube, But this will not stop me from making it in steel as I'm sure a good bit of searching through piles of offcuts should result in finding the right piece of steel and cut hands LOL!!, All I can find at the moment is 38mm by ~ 450mm Alu rods, 25mm by ~ 300mm Alu tubes and lots of 10-100mm by 25-1000mm stainless steel rods and tubes, So at the moment no steel, It would be nice to make a stainless steel suppressor but it will not be able to be blued and can be quite expensive if I go wrong, But a stainless steel suppressor would be nice as a MK2 or MK3 though.

Here is one of the 38mm by 450mm Alu rods:

Looks like this rod is just over 3 years old!

Stevie  |

|

_________________

"Who Dares Wins" - SAS 22nd Regiment Hereford. |

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Sun Jul 15, 2007 7:32 pm Posted: Sun Jul 15, 2007 7:32 pm |

|

|

| Alstone |

| Moderator & Site Supporter |

|

|

| Joined: 01 Mar 2007 |

| Posts: 4139 |

| Location: Linconshire, ENGLAND |

|

|

|

Hi Stevie stainless steel can be blued using a torch.

AL |

|

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Sun Jul 15, 2007 7:39 pm Posted: Sun Jul 15, 2007 7:39 pm |

|

|

| StevieLaner7777 |

| Moderator |

|

|

| Joined: 07 Mar 2007 |

| Posts: 1060 |

| Location: Herefordshire, UK |

|

|

|

Hi Al

Thanks for the 'heads up' on the stainless steel bluing!!

I must have had it confused with the cold bluing methods.

Still pretty costly to get wrong though, But I will definitely use Stainless for when it comes to making MK2!!

Stevie  |

|

_________________

"Who Dares Wins" - SAS 22nd Regiment Hereford. |

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Sun Jul 15, 2007 9:40 pm Posted: Sun Jul 15, 2007 9:40 pm |

|

|

| StevieLaner7777 |

| Moderator |

|

|

| Joined: 07 Mar 2007 |

| Posts: 1060 |

| Location: Herefordshire, UK |

|

|

|

Suppressor update:

I have decided to use only three baffles in the entire 30X200mm suppressor design (excluding the End-cap), One of these three baffles will be 'Fixed' as in it will be part of the tube As I will cut out from either side evenly but not all the way through so this will leave a 'fixed baffle exactly in the middle of the suppressor tube, I will then use two more baffles to divide the secondary expansion chamber into three.

Also, Some very basic 2D computer drawings will be coming soon to back-up my design description.

Stevie  |

|

_________________

"Who Dares Wins" - SAS 22nd Regiment Hereford. |

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Tue Aug 07, 2007 9:39 am Posted: Tue Aug 07, 2007 9:39 am |

|

|

| Alstone |

| Moderator & Site Supporter |

|

|

| Joined: 01 Mar 2007 |

| Posts: 4139 |

| Location: Linconshire, ENGLAND |

|

|

|

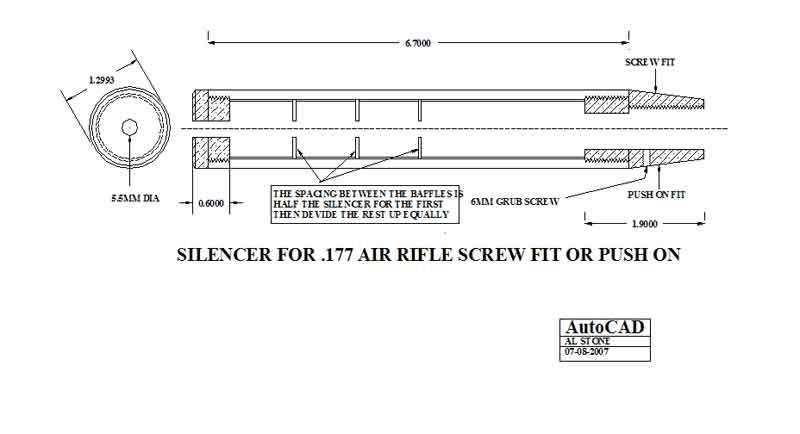

Here you are Stevie, I just got a new design packege "AutoCAD" so I thought I'd try it out on a silencer as per the above posts.

The distance pieces between the baffels can be plastic, the rest aluminium or steel. don't take to much notice of the dimension's although the general size will work well for a .177 cal at up to 800 fps.

AL |

|

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Tue Aug 07, 2007 2:00 pm Posted: Tue Aug 07, 2007 2:00 pm |

|

|

| StevieLaner7777 |

| Moderator |

|

|

| Joined: 07 Mar 2007 |

| Posts: 1060 |

| Location: Herefordshire, UK |

|

|

|

Hi Al

That's what I need! "AutoCAD" Do you know if there are any 'free-trial' versions of that program?

Thanks for the Technical drawing! I'm sure I will use it, It's exactly how I described it to be also as I will be making a Push-on Suppressor with a grub screw for the 1077 as the barrel shroud is slotted to fit the Front sight that I have already cut level with the shroud when I fitted the other suppressor on awhile back, This slot would make it very difficult to thread.

Now that I have the Diagram I think I might be able the start making it, One Q though: Do you use a manual tap and dye set to thread either end the the suppressor tube and the end caps or somthing else???

Thanks again Al, I'll be printing it of now!

Stevie  |

|

_________________

"Who Dares Wins" - SAS 22nd Regiment Hereford. |

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Tue Aug 07, 2007 4:52 pm Posted: Tue Aug 07, 2007 4:52 pm |

|

|

| Alstone |

| Moderator & Site Supporter |

|

|

| Joined: 01 Mar 2007 |

| Posts: 4139 |

| Location: Linconshire, ENGLAND |

|

|

|

Hi Stevie

you need to use the lathe to cut the thread on the barrel end, but if you are going to make it a push on unit thats not necessary, the front end is not so critical but I would still try and thread it in the lathe, even if you use hand taps and dies.

To tap a female hole using a hand tap on a lathe put the tube in the chuck and the tap in a drill chuck in the tail stock, start up the lathe in very slow speed about 15-30 rpm,push tap in the tail stock up to the tube do not lock the tail stock, and apply pressure until the tap bites then let it pull itself in to the tube, when it gets to the correct depth undo the drill chuck and slide the tail stock back out of the way and remove the tap by hand, repeat with a finishing tap.

For a male thread put the piece to be threaded in the chuck, put the die in a hand wrench, put a large chuck in the tail stock, put the die up against the piece to be threaded and slide the tail stock up to the die, adjust the drill chuck so that the jaws are pushing on the back of the die, lock the tail stock then turn the chuck by hand to get the die to bite at the same time putting pressure on the die by winding out the tail stock chuck, make sure that one of the die wrench handles is resting on the side of the bed to stop it from turning.

I hope you can make sense of this if not I,ll post some photos of the setup

Al |

|

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Tue Aug 07, 2007 7:28 pm Posted: Tue Aug 07, 2007 7:28 pm |

|

|

| StevieLaner7777 |

| Moderator |

|

|

| Joined: 07 Mar 2007 |

| Posts: 1060 |

| Location: Herefordshire, UK |

|

|

|

Hi Al

I understand what your talking about, But if I'm unclear about anything whilst I'm making it I will give you a shout before doing it, Thanks for the info though! I now know the theory of threading using a lathe now, But practically doing it may be a different matter, So I guess I will be starting to make it when my old man gets some time of work (Hopefully soon), I've just got around to making some proper work space in the garage to actually be able to efficiently do something without having to lean over another bloody motorbike LOL.

Stevie

P.s. Sorry about taking so long replying! I hope I didn't keep you waiting around, I think everyone knows by now that I take about an hour or so to process my reply so they log of and come back later, Sorry! |

|

_________________

"Who Dares Wins" - SAS 22nd Regiment Hereford. |

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Thu Aug 09, 2007 8:01 am Posted: Thu Aug 09, 2007 8:01 am |

|

|

| johncedarhill |

| Member |

|

|

| Joined: 16 Jul 2007 |

| Posts: 14 |

|

|

|

|

Are Grub screws self tapping??

Thanks |

|

_________________

God Bless the Troops! |

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Thu Aug 09, 2007 8:30 am Posted: Thu Aug 09, 2007 8:30 am |

|

|

| johncedarhill |

| Member |

|

|

| Joined: 16 Jul 2007 |

| Posts: 14 |

|

|

|

|

Could this work for ,22 as well? What is the ID of the tubing?

thanks |

|

_________________

God Bless the Troops! |

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Wed Aug 15, 2007 12:16 pm Posted: Wed Aug 15, 2007 12:16 pm |

|

|

| Alstone |

| Moderator & Site Supporter |

|

|

| Joined: 01 Mar 2007 |

| Posts: 4139 |

| Location: Linconshire, ENGLAND |

|

|

|

Hi johncedarhill

Sorry about the delay in replying, Grub screws are just a thread with an Allan key slot in one end, they not self tapping.

They are a handy way of fastening collars etc without having a bolt head sticking out.

As for the silencer if you are going to use it for .22 make the bore 6.5mm, and the outer dia of the tube is 1 1/4" or 30mm, the general size is not to critical.

I hope that helps.

AL |

|

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Wed Aug 15, 2007 12:54 pm Posted: Wed Aug 15, 2007 12:54 pm |

|

|

| johncedarhill |

| Member |

|

|

| Joined: 16 Jul 2007 |

| Posts: 14 |

|

|

|

|

| Thank you. I did find a source for grub screw which is called here socket head. I grew up with allen wrench. |

|

_________________

God Bless the Troops! |

|

|

|

|

|

|  |  |  | | | |  |  |

Note: If you are seeing "Please enter your username and password to log in." Your browser cookies have been reset

or you need to register to access the topic in question. Use the 'Register' button near the top left of this page.

|