|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Fri Jun 22, 2007 10:45 am Posted: Fri Jun 22, 2007 10:45 am |

|

|

| StevieLaner7777 |

| Moderator |

|

|

| Joined: 07 Mar 2007 |

| Posts: 1060 |

| Location: Herefordshire, UK |

|

|

|

Alstone Wrote:

| Quote: |

Hi Stevie why do you want to stabilize the barrel , does it move about in the shroud ?,also on your gun does it run off center from the breach end, looking at the photo it seem's to me that the barrel is looking up and the shroud is looking down, which would annoy me. If you fill the shroud with foam can you still get the barrel out ?.

By the way congratulations on the work you have done on 1077 there will be no stopping you now.

AL |

Hi Al

The reason for why I want to stabilize the barrel on the Crosman 1077W is because the barrel is only thin, As AirGunEric says "Soda Straw Barrel", And the barrel is not made of what I would call 'rigid' steel, So the barrel tends to vibrate causing the pellets to be Inaccurate on long ranges.

Yes!! the barrel does tend to "look up and the shroud" but the shroud is in line with the rest of the Rifle, AirGunEric and I have discussed this feature before.

If I coat the inside of the Shroud and the outside of the barrel with Grease or Oil, Hopefully the Expanding foam will not Stick to it.

Thanks for the Compliment!! The mods will keep on coming!

Stevie

P.s. Looks like AirGunEric has beaten me to this post!! |

|

_________________

"Who Dares Wins" - SAS 22nd Regiment Hereford. |

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Fri Jun 22, 2007 11:19 am Posted: Fri Jun 22, 2007 11:19 am |

|

|

| Alstone |

| Moderator & Site Supporter |

|

|

| Joined: 01 Mar 2007 |

| Posts: 4139 |

| Location: Linconshire, ENGLAND |

|

|

|

I used to use silicon spray to stop foam from sticking to steel parts on textile machinery, it worked quie well.

AL |

|

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Fri Jun 22, 2007 11:25 am Posted: Fri Jun 22, 2007 11:25 am |

|

|

| StevieLaner7777 |

| Moderator |

|

|

| Joined: 07 Mar 2007 |

| Posts: 1060 |

| Location: Herefordshire, UK |

|

|

|

Thanks for the Tip Al.

But First, I will experiment with some copper pipe before going ahead with it.

Stevie  |

|

_________________

"Who Dares Wins" - SAS 22nd Regiment Hereford. |

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Sat Jun 23, 2007 8:32 am Posted: Sat Jun 23, 2007 8:32 am |

|

|

| StevieLaner7777 |

| Moderator |

|

|

| Joined: 07 Mar 2007 |

| Posts: 1060 |

| Location: Herefordshire, UK |

|

|

|

Hi

I will be going to B&Q today to get some expanding foam, So I'll tell you how it goes on the copper pipe later.

Q: How long does Expanding foam take to set??

Stevie  |

|

_________________

"Who Dares Wins" - SAS 22nd Regiment Hereford. |

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Sat Jun 23, 2007 9:01 am Posted: Sat Jun 23, 2007 9:01 am |

|

|

| Alstone |

| Moderator & Site Supporter |

|

|

| Joined: 01 Mar 2007 |

| Posts: 4139 |

| Location: Linconshire, ENGLAND |

|

|

|

| About 30 minutes on a warm day, probably quicker |

|

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Sat Jun 23, 2007 9:30 am Posted: Sat Jun 23, 2007 9:30 am |

|

|

| StevieLaner7777 |

| Moderator |

|

|

| Joined: 07 Mar 2007 |

| Posts: 1060 |

| Location: Herefordshire, UK |

|

|

|

Cheers Al!!

Stevie  |

|

_________________

"Who Dares Wins" - SAS 22nd Regiment Hereford. |

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Sun Jun 24, 2007 4:57 pm Posted: Sun Jun 24, 2007 4:57 pm |

|

|

| Alstone |

| Moderator & Site Supporter |

|

|

| Joined: 01 Mar 2007 |

| Posts: 4139 |

| Location: Linconshire, ENGLAND |

|

|

|

Stevie

If the problem is vibration of the barrel and you have to move the inner barrel to free off bad pellets, and if you foam the inner barrel to the outer shroud this will not be possible. Why not try getting a piece of tube that fits over the barrel and inside the shroud, it can be aluminum, brass or steel and foam the barrel inside the new tube, it will make it ridged and still allow it to move inside the shroud. Or maybe this is not possible on you model of gun.

AL |

|

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Sun Jun 24, 2007 5:43 pm Posted: Sun Jun 24, 2007 5:43 pm |

|

|

| AirGunEric |

| Site Admin |

|

|

| Joined: 20 Jan 2007 |

| Posts: 6908 |

| Location: "Out There" |

|

|

|

Barrel vibration is actually far away from the issue on a typical 1077- it's barrel "wobble"- the barrel is only centered at the front of the shroud/muzzle by the front site mount- so it can wobble around in there. The rear of the barrel is retained quite well by the breech tabs and the clips that can be shifted in order to clear jams. This is why I suggest the packing of the barrel inside the shroud can be "overdone"- only the front really needs to be stabilized.

Maybe once everything is stable in this respect- small vibrations would become an issue- but I don't think that should be a major concern. Kind of like the kid with the finger in the dyke as the water is rushing over the top. |

|

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Sun Jun 24, 2007 8:21 pm Posted: Sun Jun 24, 2007 8:21 pm |

|

|

| StevieLaner7777 |

| Moderator |

|

|

| Joined: 07 Mar 2007 |

| Posts: 1060 |

| Location: Herefordshire, UK |

|

|

|

Hi Alstone + Eric

OK.. I've been experimenting with the expanding foam lately and have come to a conclusion that no matter what oil, grease or silicon spray I use, It's going to either end up sticking to it or as Eric said "become a sticky mess".

I've also found out that the expanding foam doesn't seem to be expanding in the pipe!?!, It appears to be just sticking to the copper outer pipe and the alu inner pipe with a big air gap between the two!?!

So my solution to these problems is to lightly oil the barrel, Then wrap some cling film around it, After the expanding foam has set in the shroud the barrel should just slide out from the cling film (Hopefully)

Though if this method proves problematic, I might dump the whole 'Expanding foam' idea, And get some small type plumbing insulation (15mm OD x 8mm ID) to fit 1/4 to 1/3 of the way down the barrel shroud from the muzzle end.

Also: What is a "dyke" Eric??

Over here in Herefordshire 'Dyke' means Lesbian!!

Stevie  |

|

_________________

"Who Dares Wins" - SAS 22nd Regiment Hereford. |

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Sun Jun 24, 2007 9:46 pm Posted: Sun Jun 24, 2007 9:46 pm |

|

|

| AirGunEric |

| Site Admin |

|

|

| Joined: 20 Jan 2007 |

| Posts: 6908 |

| Location: "Out There" |

|

|

|

| Yes, "dyke" has the same 'social' definition here- generated by the tale of the boy with his finger in the dyke- as per my example. A dyke would be a dam- as in to hold water back. Now we have the tale of the young lad who found a leak through a small hole in one, so he puts his finger in it to stop the leak. You can probably gather how they attached the term "dyke" to "lesbian" fairly easily now... |

|

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Mon Jun 25, 2007 7:20 pm Posted: Mon Jun 25, 2007 7:20 pm |

|

|

| StevieLaner7777 |

| Moderator |

|

|

| Joined: 07 Mar 2007 |

| Posts: 1060 |

| Location: Herefordshire, UK |

|

|

|

Hi All

Thanks for the explanation Eric, I thought it had something to do with dams, But as usual I wasn't too sure.

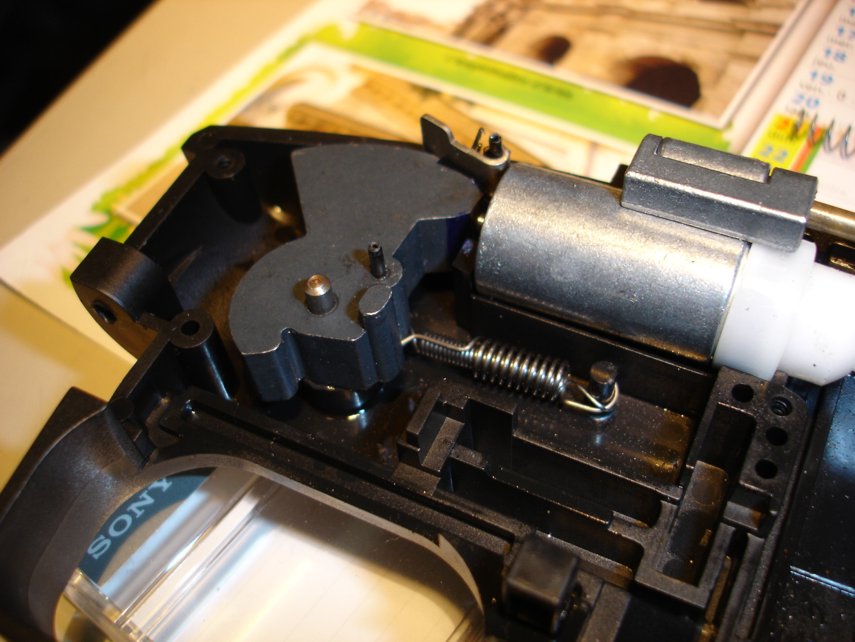

Lately I've had my 1077 in pieces as part of the 'Expanding Foam' Mod, So I thought I'd hit two birds with one stone and have a look into the valving and plumbing of the 1077 as well.

Looks like a Chrony is going to be on my wish-List very soon!!

Stevie  |

|

_________________

"Who Dares Wins" - SAS 22nd Regiment Hereford. |

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Mon Jun 25, 2007 8:11 pm Posted: Mon Jun 25, 2007 8:11 pm |

|

|

| AirGunEric |

| Site Admin |

|

|

| Joined: 20 Jan 2007 |

| Posts: 6908 |

| Location: "Out There" |

|

|

|

If you come up with a good replacement or alteration to the stock valve spring- post it up with details (I haven't yet gotten to butchering mine yet- and I've been humming and hawing about ordering a "mixed bag" of springs to see what I might get that could be usable).

That Chronoscope/Combro chronograph seems to be reasonably inexpensive for guys in the UK, I know Al has one- and the PC interface is super-cheap! If you get one of these- give us a review of it! |

|

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Mon Jun 25, 2007 9:25 pm Posted: Mon Jun 25, 2007 9:25 pm |

|

|

| StevieLaner7777 |

| Moderator |

|

|

| Joined: 07 Mar 2007 |

| Posts: 1060 |

| Location: Herefordshire, UK |

|

|

|

Hi Eric

If I do find a more suitable valve spring for the 1077, I'll let you and every other 1077 owner with a Internet connection and a brain know!!

As for butchering the stock valve spring: That's out of the question, As I prefer to keep original parts exactly how they are.

When I get round to buying a chrony, Whether it be the Chronoscope/Combro or any other type of chrony, I will post a full review on it for all!!

Stevie  |

|

_________________

"Who Dares Wins" - SAS 22nd Regiment Hereford. |

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Sat Apr 11, 2009 3:50 am Posted: Sat Apr 11, 2009 3:50 am |

|

|

| Lescarroz |

| New Member |

|

|

| Joined: 24 Feb 2009 |

| Posts: 4 |

|

|

|

|

| AirGunEric wrote: |

Mod 9) Install more weight on the rear of the hammer (solder, glue on some lead maybe) - part #1077030- and/or tighten the pull of the hammer spring (part #106035) by either using a tighter spring itself, or cutting about 8mm (5/16") off the existing hammer spring steel and re-bend as appropriate to re-attach it. The idea here is to have the hammer hit the valve stem harder and hopefully a bit longer in order to ensure the maximum amount of Co2 gets through the plumbing to the pellet. Note: tightening the hammer spring increases trigger pull, adding to the hammer's weight won't.

|

Hi AirGunEric.

First of all, excuse my bad English languages.

Your explanation is very interesting.

I tried this modification [Mod9], but unfortunately this change nothing, any difference in the chrony.

2 spring for hammer

[img] [/img] [/img]

Hammer's weight

[img] [/img] [/img]

I don't understand why !

Could you explain my ? |

|

|

|

|

|

|

|  |  |  | | | |  |  |

|  | | | |  |  |  |  | |  | |  |  |  |

Posted: Sat Apr 11, 2009 6:16 am Posted: Sat Apr 11, 2009 6:16 am |

|

|

| Alstone |

| Moderator & Site Supporter |

|

|

| Joined: 01 Mar 2007 |

| Posts: 4139 |

| Location: Linconshire, ENGLAND |

|

|

|

Welcome to airgunhome Lescarroz, I don’t have a 1077 But I do use a .177 Rohm pistol and I find that the weight on the hammer makes a lot of difference provided the co2 pressure is high, but on a cold day it‘s better without it, but so far altering the hammer spring makes no difference at all, unless you open up the porting to get a better gas flow.

That’s just my findings with a similar system, someone who knows more about the 1077 will probably be able to help you more.

Nice photo's.

Al |

|

_________________

|

|

|

|

|

|

|  |  |  | | | |  |  |

Note: If you are seeing "Please enter your username and password to log in." Your browser cookies have been reset

or you need to register to access the topic in question. Use the 'Register' button near the top left of this page.

|